Thermal oil solutions you can rely on.

Therminol® 59: a heat transfer fluid with excellent low-temperature pumping characteristics and thermal stability

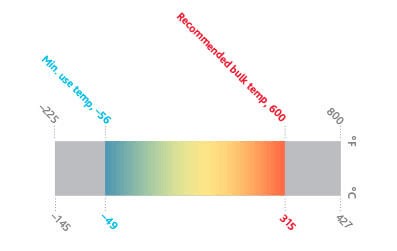

The synthetic heat transfer fluid Therminol® 59 provides superior pumpability at low temperatures (pumpable at -49°C), ensuring trouble-free starts in cold climates while maintaining thermal stability at a recommended operating temperature of 315°C. Therminol® 59 is available worldwide.

Temperature range

-49° to 315°C

Recommended bulk temp °C

315

Max. film temp °C

345

Boiling point °C @ 1013 mbar

289

Pumpability °C @ 300 mm²/s (cSt)

-37

Pour Point °C

-68

Flash Point °C (ASTM D93)

132

Flash Point °C (ASTM D92)

146

Autoignition Temp °C (DIN 51794)

404

Density @ 20°C (kg/m³)

974

Kinematic viscosity @ 40°C (mm²/s)

4,04

Water Class

WGK 3

Your advantages of using Therminol® 59 in your thermal oil systems

-

Heating or cooling operations – Therminol® 59 has a surprisingly low viscosity for a high-temperature heat transfer fluid. It's ideal for combined heating and cooling applications, delivering excellent heat transfer rates even at 20°C. For batch processes, Therminol® 59's exceptional cooling performance is a key advantage.

-

Superior low-temperature pumpability – the low viscosity at extremely low temperatures makes it an ideal fluid for northern climates. In fact, Therminol® 59 was originally developed for use in Alaska's North Slope, providing an exceptional test of its low-temperature pumpability.

-

Long life means low costs – operators of thermal oil systems can count on years of reliable, trouble-free operation, even when Therminol® 59 is continuously operated at its recommended maximum temperature of 315°C. A long service life means fewer fluid changes, translating into lower operating costs – a critical advantage in today's competitive business environment.

Discover a wide range of the most common applications for Therminol® 59:

-

Oil and gas processing

-

Natural gas purification

-

Gas-to-liquid (GTL) applications

-

Plastics and polymer manufacturing

-

Plastic injection molding

-

Specialty chemical production

-

Organic rankine cycle (ORC)

-

Biofuel production

-

Water desalination

Increase your Therminol® 59 knowledge with our comprehensive resources:

- Therminol 59 Safety Data Sheet (DE)

- Therminol 59 Safety Data Sheet (EN)

- Therminol 59 Safety Data Sheet (IT)

- Therminol 59 Safety Data Sheet (PL)

- Therminol 59 Technical Data Sheet (EN)

- Therminol 59 Product Information (EN)

- Therminol Medium Temperature heat transfer fluids (EN)

- Therminol Wärmeträgeröle Produktübersicht (DE)

- Therminol Heat Transfer Fluids selection guide (EN)

- Heat Transfer Fluids – Mehr als 50 Jahre erfolgreiches Temperaturmanagement (DE)

- Heat Transfer Fluids – More than 50 Years of Experience in Managing Temperature (EN)

- Thermoölanlagen sicher und effizient betreiben – White Paper (DE)

- Operating Thermal Oil Plants safely and reliably – White Paper (EN)