Thermal oil solutions you can rely on.

Therminol® D-12: trusted heat transfer fluid for industrial applications

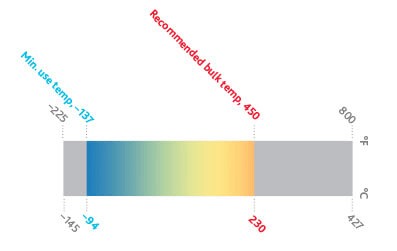

Designed for both heating and cooling, Therminol® D-12 performs exceptionally well, even at a wide range of temperatures, down to -94°C to 190 °C without overpressure and up to 230 °C with pressurization.

Ideal for batch processes and refrigeration loops, Therminol® D-12 ensures optimal performance without the need for steam or electrical tracing, eliminating common start-up issues. Therminol® D-12 enhances system reliability and reduces downtime.

Temperature range

-94° to 230°C

Recommended bulk temp °C

230

Max. film temp °C

245

Boiling point °C @ 1013 mbar

192

Pumpability °C @ 300 mm²/s (cSt)

-82

Pour Point °C

<-100

Flash Point °C (ASTM D93)

62

Autoignition Temp °C (DIN 51794)

277

Density @ 20°C (kg/m³)

762

Kinematic viscosity @ 40°C (mm²/s)

1,23

Water Class

WGK 1

Approval

NSF HT1

Your benefits from using Therminol® D-12 in your thermal oil systems

-

Heating or cooling operation – Therminol® D-12 is ideally suited for combination heating and cooling applications and delivers excellent heat transfer rates even at -45°C. Batch processes will benefit from the excellent cooling performance Therminol® D-12 delivers. Therminol® D-12 can also be used as a secondary coolant or "brine" in refrigeration loops where a broad range of properties is desired.

-

Easy operation – using Therminol® D-12 avoids the problems of using multiple fluids in the same piece of equipment.

-

Low cost – Therminol® D-12 delivers better thermal performance at lower cost than many competing fluids.

-

Low odor and excellent toxicity profile – Therminol® D-12 is NSF registered with HT1 status, surpassing requirements for use where there is the possibility of incidental food contact.

Discover a wide range of the most common applications for Therminol® D-12:

- HTF - active pharmaceutical ingredients

- Pharmaceutical processing

- Environmental test chambers

- Specialty and batch chemical manufacturing

- Food & beverage processing

Increase your Therminol® D-12 knowledge with our comprehensive resources:

- Therminol D-12 Safety Data Sheet (DE)

- Therminol D-12 Safety Data Sheet (EN)

- Therminol D-12 Safety Data Sheet (IT)

- Therminol D-12 Safety Data Sheet (PL)

- Therminol D-12 Technical Data Sheet (EN)

- Therminol D-12 Product Information (EN)

- 12 Reasons to choose Therminol D-12 (EN)

- Therminol Wärmeträgeröle Produktübersicht (DE)

- Therminol Heat Transfer Fluids selection guide (EN)

- Heat Transfer Fluids – Mehr als 50 Jahre erfolgreiches Temperaturmanagement (DE)

- Heat Transfer Fluids – More than 50 Years of Experience in Managing Temperature (EN)

- Thermoölanlagen sicher und effizient betreiben – White Paper (DE)

- Operating Thermal Oil Plants safely and reliably – White Paper (EN)